Felt Flap Discs is specially designed for mirror finishing & polishing requirements.

It's different like normal flap discs and the disc's density can be 2.0g/cm3 to 8.0g/cm3 which provide cooler & flexible polishing performance.

The felt flap disc can be used to eliminate scratches and brighten the surface. It can also be used as one of the combined polishing wheels to eliminate scratches on shallow surfaces. It can be used with polishing powder coolant.

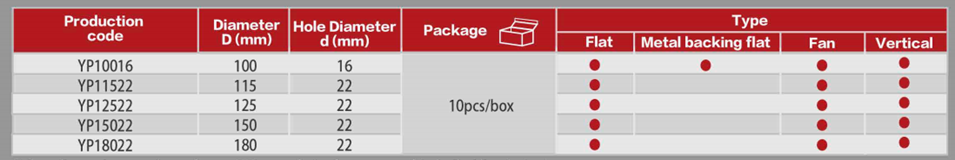

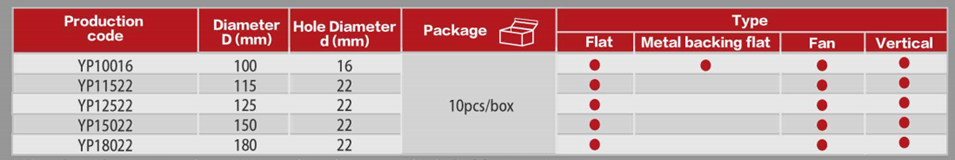

| Application | ·Polishing And Mirror Finishing ·Marble Polishing ·Hardware Work Piece Mirror Polishing ·Cleaning The Surface Of Non-Ferrous Metal ·Polish In The Last Step Of The Process, Cleanliness Can Achieve Mirror Effect. | Brand | KEYING | Commodity Code | YDFLT2710016+Grit |

| Compatible Tool | Angle Grinder Cordless Angle Grinder | Country Of Origin | China | Raw Material | High Quality Wool mported From Australia |

| Backing | Fibre Plastic | For Use On | Glass Stainless Steel Non-ferrous Metal Aluminum Alloy Products | Grade | Medium Soft Medium Hard |

| Diameter Metric | 4"/4.5"/5" | Industries | Machinery Processing, Hardware, Casting, Auto Parts, Aviation, High-Speed Train, Ship And Other High Precision Processing And Manufacturing Industries | Hole Diameter | 16mm/22mm |

| Maximum RPM | 7700-10000 | Using Effect | Fine Polishing Mirror Effect | Standard Pack Quantity | 10pcs |

Felt materials can make of different densities, thicknesses, and hardness, with fiber-glass backing or plastic backing.

A firmer version is suggested to polish fat components and prepare for finer processing.

The softer version is more suitable for more gloss and shining surfaces.

Three different shapes allow the felt discs to apply to complicated geometries.

Polishing and mirror finishing

Marble polishing

Hardware work piece mirror polishing

Cleaning the surface of non-ferrous metal

Polish in the last step of the process, cleanliness can achieve mirror effAect.

For best performance, use with a recommended cutting speed of 5–10 m/s. This provides an ideal compromise between stock removal rate, surface quality, thermal load on the work piece and tool wear.

Felt points and discs:

Use diamond polishing pastes and polishing paste bars.

Use polishing and grinding pastes.

When changing the polishing paste, use a brand-new polishing tool.

Angle grinder

Cordless angle grinder

Please try to choose operation indoors environment and wear protective guards and goggles.

Never to exceed the recommanded maximum permitted rotational speed for safety reasons.

In order to have a gppd syocl removal rate, quality of surface and thermal laoding on the workpiece, the best performace would with a recomended cutting speed at 15-20m/s.

Don't push and increase the pressure during the processing to achieve a finner surface looking, but try to switch to diffirent grit flap wheels.

The clamping lenght between shank and grinders should be more than 15mm.

Never exceed the maximum safe speed when the shank is extra long. Try to consult your sales to check the safety rotating speed before use.

Keying Abrasives in 2024 China International Hardware Show!

Find more

「INVITATION」KEYING ABRASIVES invites you to meet in 2024 China International Hardware Show

Find more

Keying Abrasives in 2023 Zhengzhou International A&G EXPO

Find more

Find more