The non-woven abrasive flaps are stuck to a glass-fabric backing pad, meaning that the discs can be used face-down. Long tool life is achieved through the dense packing of the flaps.

The tool is designed for working on large surfaces with speed-adjustable angle grinders.

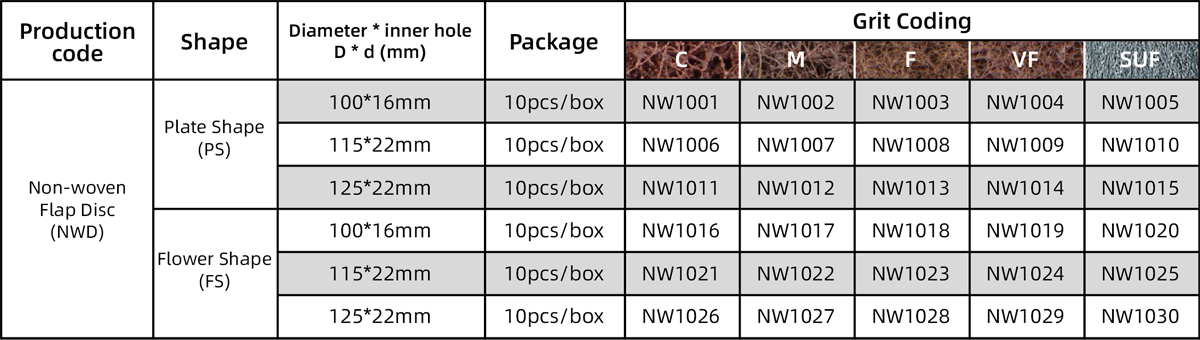

▶ Type: Plate Shape

▶ Max. RPM: 7000~19000 RPM

▶ Outer Diameter: 100mm/115mm/125mm/150mm/175mm

▶ Centre Hole Diameter: 16mm/22mm

▶ Raw Materials: Aluminum Oxide(AO), Silicon Carbide(SC)

▶ Grit Size: Coarse-60#/80#, Medium-100#/120#, Fine-150#/180#, Very Fine-240#/320#, Ultra Fine-400#/600#, Micro Fine-800#/1000#

1. Please try to choose an operation indoor environment and wear protective guards and goggles.

2. Never exceed the recommended maximum permitted rotational speed for safety reasons.

3. In order to have a good stock removal rate, quality of surface, and thermal laoding on the workpiece, the best performance would be with a recommended cutting speed of 15-20m/s.

4. Don't push and increase the pressure during the processing to achieve a finner surface looking, but try to switch to diffirent grit flap wheels.

The clamping length between shank and grinders should be more than 15mm.

Never exceed the maximum safe speed when the shank is extra long. Try to consult your sales to check the safety rotating speed before use.

Keying Abrasives in 2024 China International Hardware Show!

Find more

「INVITATION」KEYING ABRASIVES invites you to meet in 2024 China International Hardware Show

Find more

Keying Abrasives in 2023 Zhengzhou International A&G EXPO

Find more

Find more