What tools can 4 Inch abraisve discs usually apply with?

-Backing pads

Keying 4 inch flap disc including Paint & Striper Disc with a central hole, Paint & Striper Disc with Shank, Paint & Striper with Fibre Backing, Roloc Surface Condition 4 inch flap disc, Roloc 4 in flap disc, Self-adhesive 4 inch flap disc, Flap 4 in flap disc, Fibre 4 inch flap disc, Velcro-backed abrasive disc.

What tools can 4 Inch abraisve discs usually apply with?

-Backing pads

KEYING Paint & Striper Disc With Central Hole surrounds the grains with a resin body and is bonded to the fiber mesh.At the same time of high-speed grinding, the wear-resistant fiber mesh polishes and smooths the slip marks left on the surface of the object,not only the coating...

KEYING Paint & Striper Disc with Fibre Backing uses fiber mesh as the carrier and uses resin elastomer to firmly attach sharp abrasives to the fiber mesh. When polishing this product at high speed, the abrasive sand will not fall off and has a long service life. It can...

The Roloc Surface Condition SCM Disc is a great choice for surface work. Ideal for deburring, finishing, and cleaning on flat or contoured metal surfaces, it enables quick and easy operator assembly. Its compact design allows use in hard - to - reach areas, and the quick - change ...

Surface_Condition_SCM_Disc_with_hole-图1.webp)

The Surface Condition SCM Disc with Hole is a laminated high - performance tool. It is used for reducing surface roughness, smoothing surfaces, cleaning and removing welding seams, and deburring edges on various materials. It s suitable for all common angle grinders....

Surface_Condition_SCM_Disc-图1.webp)

We manufacture Surface Condition SCM Disc by reprocessing jumbo rolls of SCM into unique smaller-sized SCM grinding and polishing tools. These tools are adaptable to various contours, and their performance capacity is consistently good and steady ...

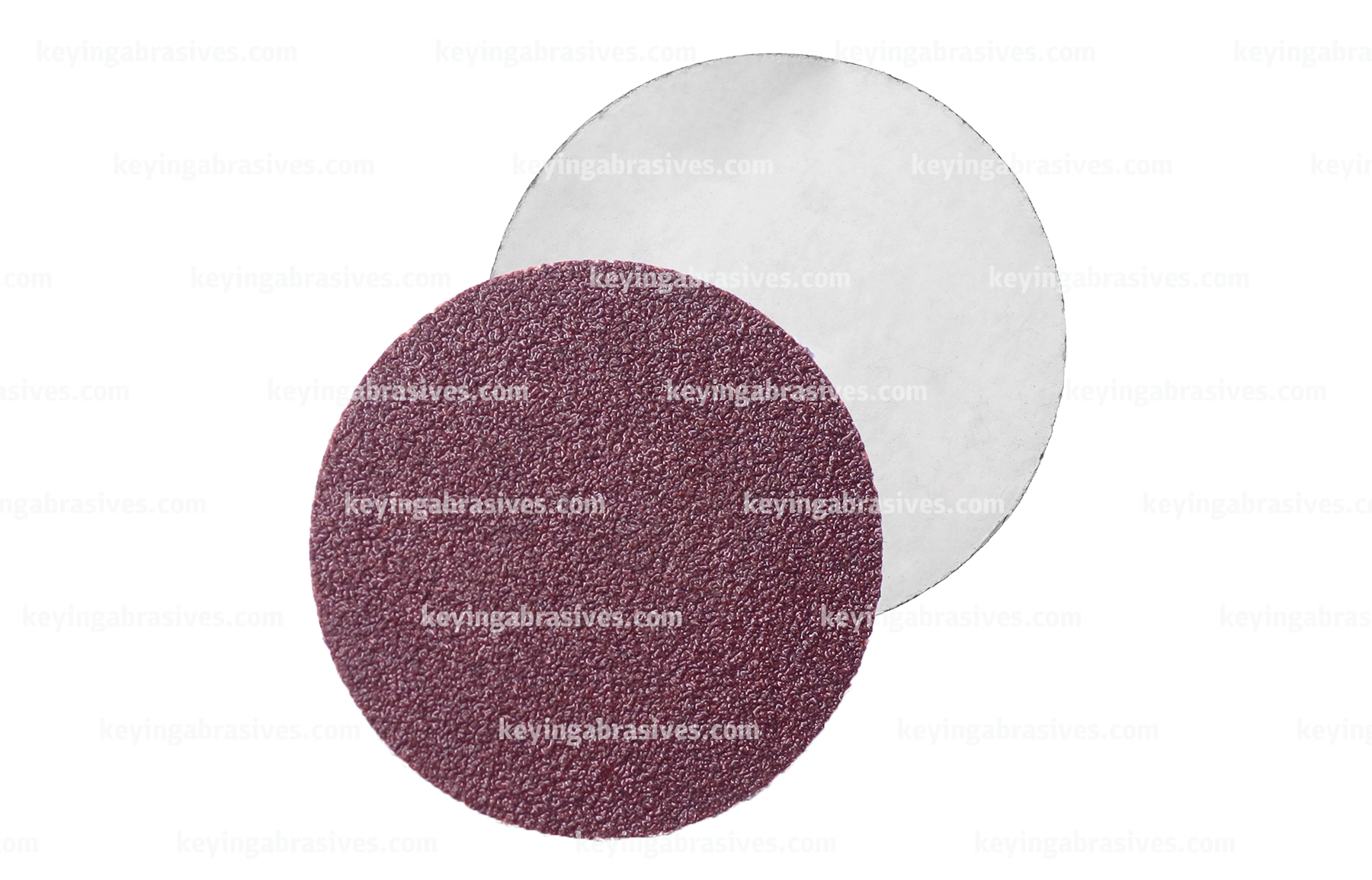

KEYING Adhesive-backing Sandpaper Disc, designed for optimal performance and longevity. They boast maximum resistance to loading, enhancing your productivity and reducing...

When working with a 100mm 4-inch flapper disc, understanding its working principles is essential for achieving optimal results. Here are key factors to consider:

Reducing Contact Pressure and Speed: To minimize wear and thermal load on the workpiece, it is recommended to reduce the contact pressure and speed. When necessary, the use of abrasive paste or oil can further assist in achieving this objective.

Use Coarse-Grit Abrasive Cloths: Instead of increasing contact pressure to enhance cutting force, choosing abrasive cloths with a coarse grit size can be more effective. This approach reduces tool wear and thermal load, ensuring efficient cutting without unnecessary strain.

Adjust Cutting Speed: A slight increase in cutting speed can result in a finer surface finish. This adjustment allows for better control and precision during the cutting process.

By following these working principles, you can effectively reduce wear and thermal load on the workpiece while optimizing the performance of your 100mm 4-inch flapper disc.

Keying Abrasives in 2024 China International Hardware Show!

Find more

「INVITATION」KEYING ABRASIVES invites you to meet in 2024 China International Hardware Show

Find more

Keying Abrasives in 2023 Zhengzhou International A&G EXPO

Find more

Find more