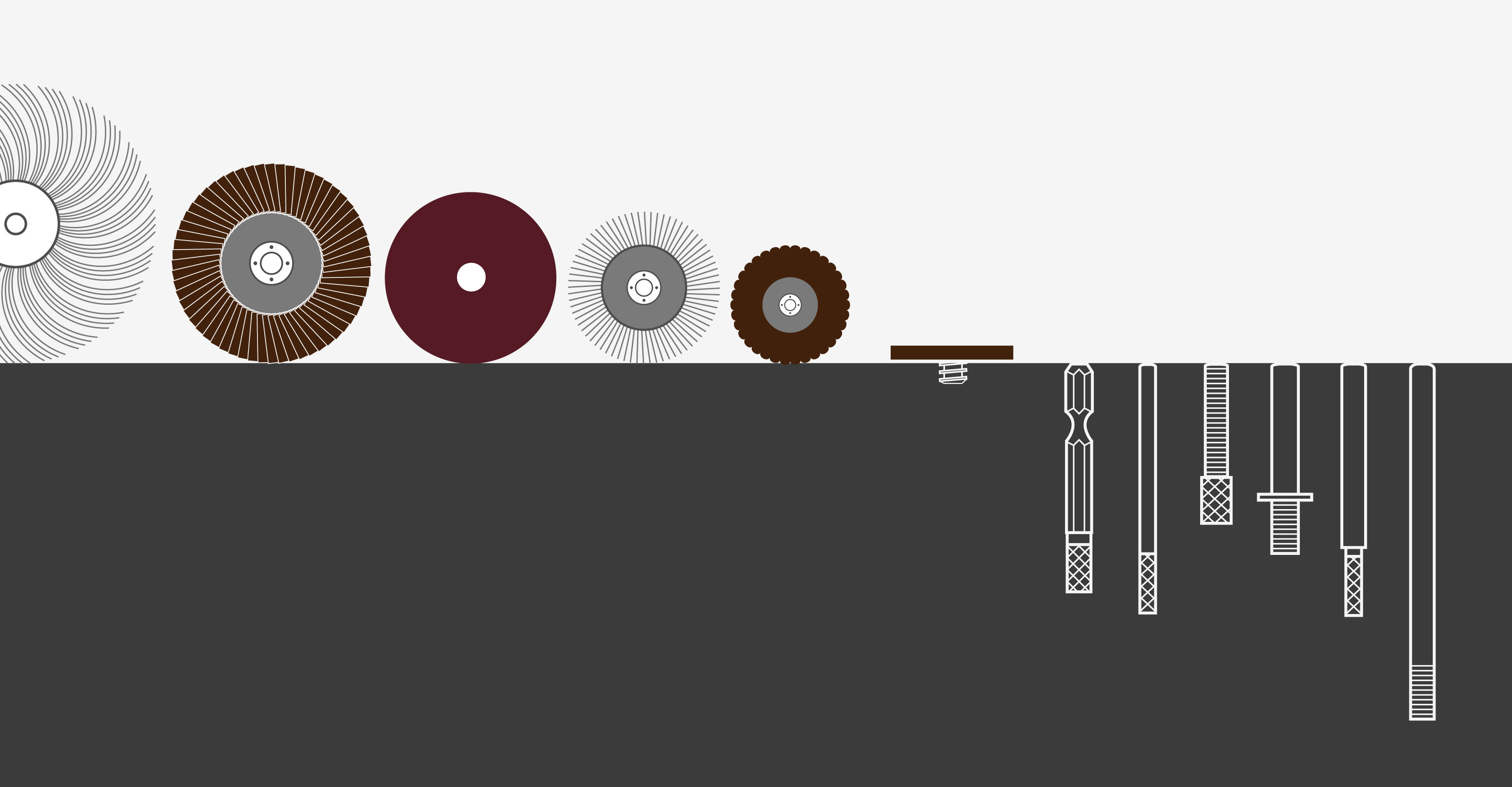

This Customize ODM flap wheel for mandrel assembly is a Straight Hole Type, common mounted flap wheels specifications have 8mm hole and 10mm hole, good idea to fit with DIY grinder or click arbor grinder.

Applications of Flap Wheels with Straight Hole for Arbor

Flap wheels with a straight hole for arbor are highly versatile and commonly used in a range of applications across various industries. The straight arbor hole allows these wheels to be mounted securely on a spindle or other rotating tool, providing stability and precision during use. Here are some typical applications:

Deburring:

Flap wheels are excellent for removing burrs from the edges of metal parts, ensuring a smooth and safe finish.

Surface Preparation:

They are used to prepare surfaces before welding, painting, or coating, helping to remove rust, scale, and old paint.

Blending and Smoothing:

These wheels blend weld seams and smooth out rough surfaces on metals, plastics, and wood.

Polishing:

They provide a high-quality polish on metal surfaces, including stainless steel, aluminum, and other non-ferrous metals.

Finishing Curved and Contoured Surfaces: The flexible nature of the flap wheel allows it to conform to complex shapes and curves, making it ideal for finishing work on tubes, pipes, and other irregular surfaces.

Grinding:

Light grinding tasks, such as removing flash from castings or refining surfaces, are effectively handled by flap wheels.

Tool and Die Maintenance:

They are used for maintaining nd polishing molds and dies, ensuring precision and extending tool life.

These flap wheels are particularly useful in industries such as metal fabrication, automotive, aerospace, and manufacturing, where high-quality surface finishing and preparation are crucial. The straight arbor hole design enhances their adaptability, making them a go-to tool for various maintenance and finishing tasks.

English

English  日本語

日本語  한국어

한국어  français

français  Español

Español  italiano

italiano  português

português  العربية

العربية  Türkçe

Türkçe  беларускі

беларускі  Indonesia

Indonesia  русский

русский