Dec 20-2017

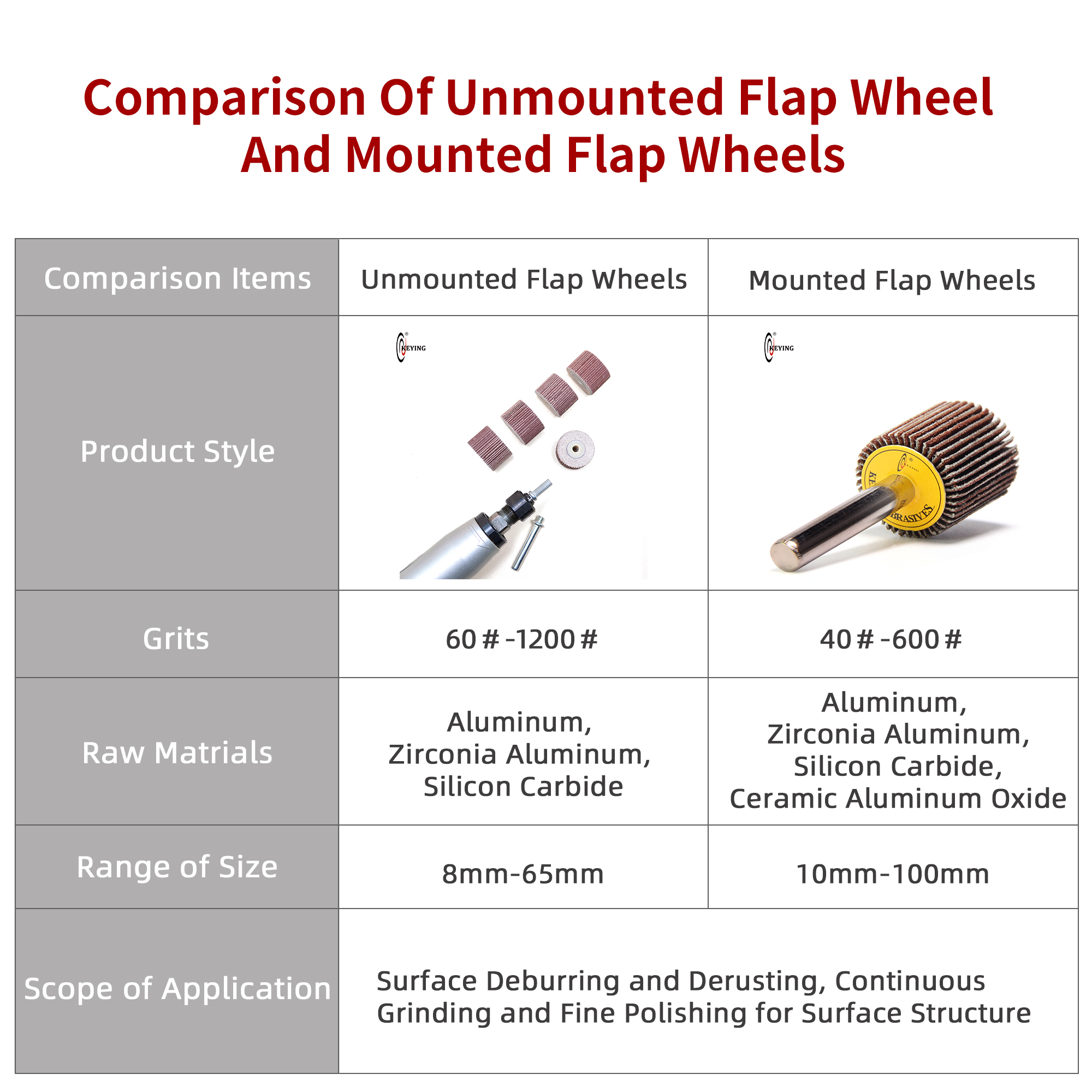

Flap wheels are versatile grinding and finishing tools used in various industrial and DIY applications. They consist of abrasive flaps arranged around a central hub, which provide a continuous supply of fresh abrasive material as they wear down. These tools for small piecework and inner holes application come in two main types: mounted flap wheel and mini unmounted flap wheel. Here's a detailed comparison between the two:

Mounting Mechanism:

Mounted flap wheels have a built-in spindle or shank, typically made of metal, which is permanently attached to the wheel.

The spindle is usually cylindrical and can vary in diameter to fit different tools.

Common spindle diameters are 1/4 inch (6 mm) and 1/8 inch (3 mm).

Tool Compatibility:

Designed to be used with portable tools like die grinders, drills, and flexible shaft tools.

The spindle is inserted into the chuck or collet of the tool, making them easy to change out quickly.

Applications:

Ideal for tasks requiring precision and control, such as deburring, blending, and finishing on small or complex surfaces.

Commonly used in metalworking, woodworking, and automotive industries for finishing intricate parts or hard-to-reach areas.

Size and Flexibility:

Typically smaller in diameter, usually ranging from 1 inch (25 mm) to 3 inches (76 mm).

Their compact size and direct attachment make them suitable for detailed and intricate work.

Ease of Use:

Simple to install and replace due to the integrated spindle.

Users don’t need to deal with additional components for mounting.

Mounting Mechanism:

Mini unmounted flap wheels do not have a built-in spindle; instead, they have a central hole or arbor hole that fits onto a separate mandrel or shaft and fast change.

The size of the central hole varies, and the wheel must be secured with a separate spindle or attachment, we called our products UNI-FLEX Mini unmounted flap wheel.

Tool Compatibility:

Typically used with stationary tools such as bench grinders or with larger handheld tools like angle grinders.

The separate mandrel allows for use with a variety of tools that have different shaft sizes.

Applications:

Suitable for inner hole or car wheel hub,Car Rim / Wheel Rim operations, such as difficult to touch and complex angers thanks for the flap wheel’s super flex and smaller size in origin pack, it will open immediately once the grinder is starting operating. It is idea for finishing smaller inside surfaces.

Common in metal fabrication, plastic, stone, woodworking, and finishing small, flat, or round surfaces.

Size and Flexibility:

Generally larger than mounted flap wheels, with diameters ranging from 3/8 inches (10 mm) up to 1/4 inches (63 mm) or more, grit size from 60#-1200#

Available in a wider range of sizes and can be used for grinding ,polishing and finishing applications.

Ease of Use:

Requires a mandrel or additional hardware to attach to the tool, and only need to change the head, leave the shank on the tool, you will have a fast change experience, which can be move from easily. See the Video to understand how to use.

More versatile in terms of the range of sizes and applications but needs proper mounting equipment.

Mounted Flap Wheels: Have an integrated spindle, used with portable tools for precision work, and are typically smaller.

Mini Unmounted Flap Wheels: Require a separate mandrel for mounting, used with stationary or smaller tools for more specific parts applications, and come in smaller sizes.

Choosing between mounted and unmounted flap wheels depends on the specific requirements of the task, the type of tool being used, and the nature of the work piece.